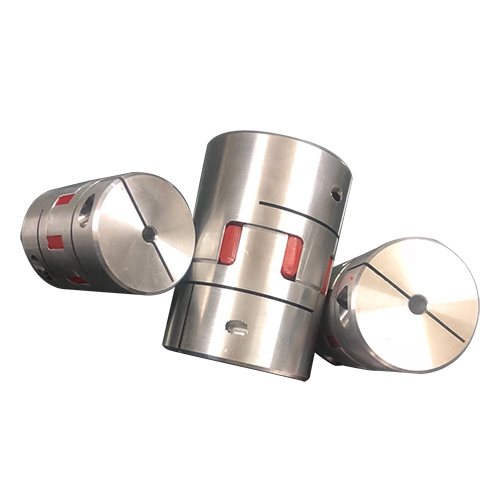

Ktr Coupling

Price 350 INR/ Unit

MOQ : 10 Units

Ktr Coupling Specification

- Sealing

- No special sealing required

- Torque

- 10 Nm 12,500 Nm (based on model)

- Max. Speed

- up to 8,000 rpm

- Connection

- Clamping or keyway

- Bore

- Customized according to shaft diameter

- Head Code

- Round

- Material

- Cast iron or steel

- Structure

- Flexible or jaw type coupling

- Standard

- DIN / ISO standard

- Inner Diameter

- 12 mm 120 mm (customizable)

- Outer Diameter

- Up to 230 mm

- Application

- Power transmission in industrial machinery, pumps, compressors, and conveyor systems

- Surface Treatment

- Blackened, rust-proof coating

- Technique

- Precision machined

- Shape

- Round

- Temperature Range

- -40C to +120C

- Tensile Strength

- 400 MPa

- Maintenance

- Low maintenance, easy to install

- Hardness

- HRC 44-48 (for metal parts)

- Coupling Type

- Jaw coupling / Gear coupling / Pin & Bush type

- Weight

- Varies from 0.5 kg to 18 kg (depending on size/model)

- Elastomer Material

- Polyurethane (for jaw coupling insert)

- Model Name/Type

- KTR Coupling (e.g., ROTEX, BoWex)

- Misalignment Compensation

- Angular, parallel, and axial misalignment

- Color

- Black

About Ktr Coupling

Unlock powerful performance and masterful engineering with KTR Coupling, available in dazzling models like ROTEX and BoWex. Grab this precision-machined solution, designed for ultimate durability with a lofty tensile strength of 400 MPa and a black, rust-proof coating. Ending soon on select offers for flexible, jaw, and gear couplings-each compensating for angular, parallel, and axial misalignments. The advanced polyurethane elastomer ensures lasting quality, while easy installation and low maintenance elevate efficiency. Perfect for pumps, compressors, conveyors, and industrial machinery. Customizable bores and round shapes suit diverse needs, meeting strict DIN/ISO standards, with high speed (up to 8,000 rpm) and impressive torque capabilities.

Exceptional Features and Material Excellence

KTR Coupling stands out with its robust cast iron or steel build, dazzling in industrial reliability and precision machining. Its blackened, rust-proof surface treatment ensures resilience, while the polyurethane jaw inserts grant flexible performance. Supporting speeds up to 8,000 rpm and torque as high as 12,500 Nm, these couplings fit round shaft connections for pumps, compressors, and conveyors. Customizable bores and shapes give adaptability on varied application surfaces, making installation straightforward and maintenance minimal.

Domestic Market Reach and Certified Supply Ability

KTR Coupling is extensively dispatched across India, catering to major domestic markets through a network of certified exporters, manufacturers, suppliers, and traders. Freight handling is streamlined and goods transport is managed efficiently to guarantee on-time delivery. Supply ability is robust, meeting the demands of diverse industry sectors, with each product adhering to stringent DIN/ISO certifications. Customers benefit from reliable dispatching and traceable freight processes, ensuring that high-quality goods arrive securely and promptly.

Exceptional Features and Material Excellence

KTR Coupling stands out with its robust cast iron or steel build, dazzling in industrial reliability and precision machining. Its blackened, rust-proof surface treatment ensures resilience, while the polyurethane jaw inserts grant flexible performance. Supporting speeds up to 8,000 rpm and torque as high as 12,500 Nm, these couplings fit round shaft connections for pumps, compressors, and conveyors. Customizable bores and shapes give adaptability on varied application surfaces, making installation straightforward and maintenance minimal.

Domestic Market Reach and Certified Supply Ability

KTR Coupling is extensively dispatched across India, catering to major domestic markets through a network of certified exporters, manufacturers, suppliers, and traders. Freight handling is streamlined and goods transport is managed efficiently to guarantee on-time delivery. Supply ability is robust, meeting the demands of diverse industry sectors, with each product adhering to stringent DIN/ISO certifications. Customers benefit from reliable dispatching and traceable freight processes, ensuring that high-quality goods arrive securely and promptly.

FAQ's of Ktr Coupling:

Q: How does KTR Coupling compensate for misalignment in industrial machinery?

A: KTR Coupling is engineered to handle angular, parallel, and axial misalignments, safeguarding equipment from damage and optimizing power transmission efficiency.Q: What materials and surface treatments are used in KTR Coupling?

A: The couplings are constructed from cast iron or steel with blackened, rust-proof coatings, and utilize polyurethane elastomer for jaw coupling inserts, enhancing strength and durability.Q: When is KTR Coupling most suitable for installation?

A: KTR Coupling is ideal for installation during machinery upgrades, maintenance cycles, or when high-performance, flexible couplings are needed for pumps, compressors, and conveyors.Q: Where can customers find KTR Coupling in India?

A: KTR Coupling is available through certified exporters, manufacturers, suppliers, and traders across various regions throughout India, ensuring accessibility and prompt supply.Q: What is the process for customizing the bore diameter of KTR Coupling?

A: Customization can be requested at the time of order, with expert precision machining ensuring the inner diameter matches the required shaft diameter according to DIN/ISO standards.Q: How do customers benefit from KTR Coupling's maintenance and installation?

A: Customers enjoy low maintenance requirements and easy installation, reducing downtime and operational costs while providing reliable, masterful connection performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Couplings Category

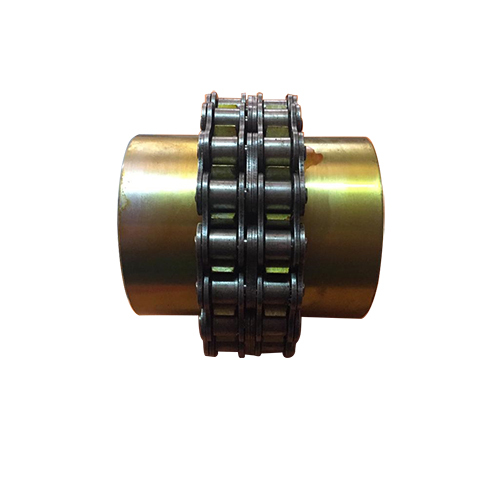

Chain Coupling

Price 360 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Metal

Usage : Industrial

Product Type : Chain Coupling

Size : Standard

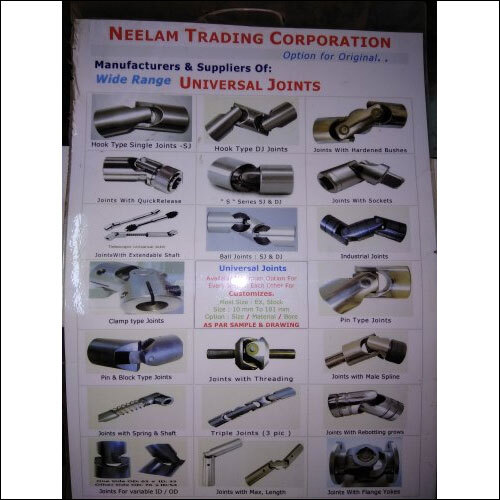

Universal Coupling

Price 350 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Usage : Industrial

Product Type : Universal Coupling

Size : Standard

Tyre Coupling

Price 110 INR / Unit

Minimum Order Quantity : 10 Units

Material : Steel

Usage : Industrial

Product Type : Tyre Coupling

Size : Standard

Universal Joint Coupling

Price 350 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Iron

Usage : Industrial

Product Type : Universal Joint Coupling

Size : Standard

Send Inquiry

Send Inquiry