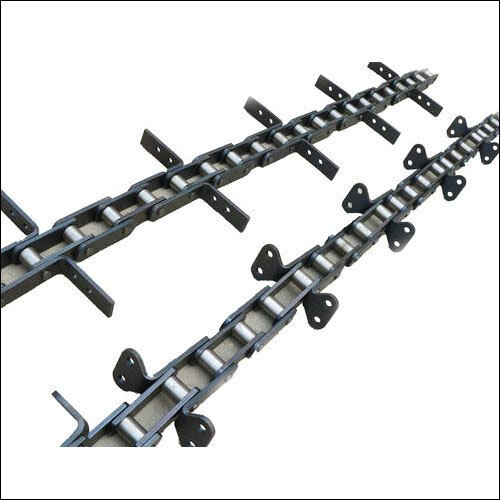

Chain Attachments

Price 5 INR/ Piece

MOQ : 1 Piece

Chain Attachments Specification

- Usage & Applications

- Industrial machinery, conveyors, power transmission

- Bore Size

- According to application requirement

- Product Type

- Chains & Sprockets

- Material

- Alloy Steel, Stainless Steel

- Surface Treatment

- Polished, Zinc Plated, Shot Blasted

- Teeth Number

- Custom as required

- Front Gear

- Available in various types

- Rear Gear

- Compatible with standard sprockets

- Size

- Standard and customized

- Attachment Type

- K1, K2, M1, M2, SA1, SA2, SK1, SK2 and customized types

- Packaging Type

- Wooden box, Carton

- Lubrication

- Pre-lubricated, maintenance-free options available

- Operating Temperature

- -20°C to 150°C

- Chain Standard

- ANSI, DIN, BS

- Manufacturing Process

- Precision machined & heat treated

- Tensile Strength

- High tensile and fatigue strength

- Pin Length

- Customizable as per specification

- Finish

- Corrosion resistant

- Chain Pitch

- Available in multiple pitches (e.g., 1/2", 5/8", 3/4")

Chain Attachments Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 1 Days

About Chain Attachments

Get top-rated chain attachments, celebrated for their high tensile and fatigue strength, featuring K1, K2, M1, M2, SA1, SA2, SK1, SK2, and custom types. These noteworthy attachments, crafted from sterling alloy and stainless steel, meet ANSI, DIN, BS standards. Available in multiple chain pitches and teeth numbers, they fit various industrial applications. Each attachment boasts corrosion-resistant finishes, precision machining, and optional maintenance-free lubrication. With customizable pin lengths and bore sizes, these attachments are engineered for excellence and offered by a leading Indian exporter, manufacturer, and supplier.

Why Industry Leaders Use Our Chain Attachments

Our chain attachments are widely used across conveyor systems, power transmission units, and heavy-duty industrial machinery by celebrated engineering firms and OEMs. The primary advantages include noteworthy durability, top-tier strength, and adaptability for both standard and custom sizes. Clients in manufacturing, packaging, and processing sectors rely on our sterling products for seamless integration into their equipment. With pre-lubricated and maintenance-free options, productivity is enhanced while minimizing downtime.

Logistics, Quotation, and Shipping Policy for Chain Attachments

All quotations are competitively prepared and provided promptly upon request. Once an order is confirmed, goods are securely packaged in wooden boxes or cartons and handed over at the designated FOB port in India. Our standardized sample policy allows clients to request samples prior to bulk orders. Payment terms are flexible, accommodating various business needs while ensuring the shipped goods arrive on schedule and in pristine condition.

Why Industry Leaders Use Our Chain Attachments

Our chain attachments are widely used across conveyor systems, power transmission units, and heavy-duty industrial machinery by celebrated engineering firms and OEMs. The primary advantages include noteworthy durability, top-tier strength, and adaptability for both standard and custom sizes. Clients in manufacturing, packaging, and processing sectors rely on our sterling products for seamless integration into their equipment. With pre-lubricated and maintenance-free options, productivity is enhanced while minimizing downtime.

Logistics, Quotation, and Shipping Policy for Chain Attachments

All quotations are competitively prepared and provided promptly upon request. Once an order is confirmed, goods are securely packaged in wooden boxes or cartons and handed over at the designated FOB port in India. Our standardized sample policy allows clients to request samples prior to bulk orders. Payment terms are flexible, accommodating various business needs while ensuring the shipped goods arrive on schedule and in pristine condition.

FAQ's of Chain Attachments:

Q: How do I select the right type of chain attachment for my machinery?

A: Identify your application requirements, such as pitch, load, operating temperature, and chain standard, then match these with our K1, K2, M1, M2, SA, SK, or custom attachments for optimal performance.Q: What materials are available for these chain attachments?

A: Our chain attachments are manufactured from sterling alloy steel or stainless steel, depending on application demands and environmental exposure.Q: When should I choose a maintenance-free, pre-lubricated option?

A: Opt for maintenance-free, pre-lubricated attachments when your operations demand minimal downtime and consistent, long-term performance with reduced lubrication intervals.Q: Where are these attachments primarily used?

A: They are predominantly used in conveyors, industrial machinery, and power transmission across various industries, including manufacturing, packaging, and processing plants.Q: What is the manufacturing process for these chain attachments?

A: Each product is precision machined and heat treated for strength and durability, then surface treated through polishing, zinc plating, or shot blasting as required.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Precision Chains Category

Standard Chains

Price 300 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel , EN series, Other

Product Type : Other, Standard Chains

Carrier Chain

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Mild steel

Product Type : Chains & Sprockets

Pusher Chain

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Mild Steel,EN series

Product Type : Pusher Chain, Other

Paver Chain

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Product Type : Paver Chain, Other

Send Inquiry

Send Inquiry